Capabilities

Dyno Manufacturing strives every day to establish ourselves as an industry leading manufacturer in the hand hygiene and facilities sanitation market. Our in house capabilities coupled with our strategic partnerships ensure that we have a solution that fits every need imaginable.

Dyno Operations & Facility

- 25,000 square foot plant facilities centrally located in the US

- Fully equipped research and product development lab

- Experienced chemists on staff to help in new product/formula development

- Multiple blending vessels and mixers to manufacture a wide variety of products

- Multiple production lines with fully automated capability to run package sizes ranging from 1 fl. Oz to 1 Gallon containers

- Warehousing of raw materials and finished goods

- Advanced reverse osmosis water purification system

- Multiple filling machines capable of filling an array of thin and viscous products

- Multiple capping machines

- Induction sealing and ink jet coding equipment

- Automatic labeling machines with capability for wrap or two sided labeling

Strategic Partnerships & Distribution

- Decades of relationships with key partners in the chemical manufacturing space

- Unparalleled access to raw materials and containers from hundreds of vendors

- Contract manufacturing partners in close proximity to keep logistical costs low

- Key relationships with industry innovators and leaders in our market

- Wide array of finished goods in inventory and ready for immediate shipping

- Distribution channels and partners positioned centrally in the US to service coast to coast with expedience and accuracy

- Systems based solutions for facilities cleaning and maintenance

- Green Certified product lines proved to be safe and effective

Quality Assurance

- cGMP (current Good Manufacturing Practices) compliant facility and standard operating procedures

- Multi-step controls to ensure accuracy and safety of all goods manufactured

- Thorough testing and material identification for all incoming raw materials

- Procedures for storage and handling of all raw materials and finished goods

- Finalized testing and C of A rendered with every shipment of finished goods at customer request

Formula Development

- Working together with our customers to best determine needs on custom formulas or manufacturing of an existing formula.

- Industry leading R&D to ensure the highest quality possible.

- Partners across multiple industries give access to the widest assortment of raw materials available.

- cGMP inspected facility and manufacturing standards ensure consistency to every blend we manufacture.

Our Private Label Process

Midwest’s leading hand hygiene & personal care product manufacturer with end to end service capabilities. We can guide your initial formula development through final ship out. We’re fully turn key which allows us to provide your organization with the specific services you need.

Formula Development

Our industry leading R&D department works hand in hand with our customers to help them dial in a formula that fits their exact needs. With a fully equipped lab and access to a wide array of raw materials, we have the tools and experience to bring your product to life.

Graphic Design

In addition to our production facilities, we also have a team of graphic designers to help bring your brand to life. What starts as an idea in your head comes to life as a beautiful and professionally designed product label.

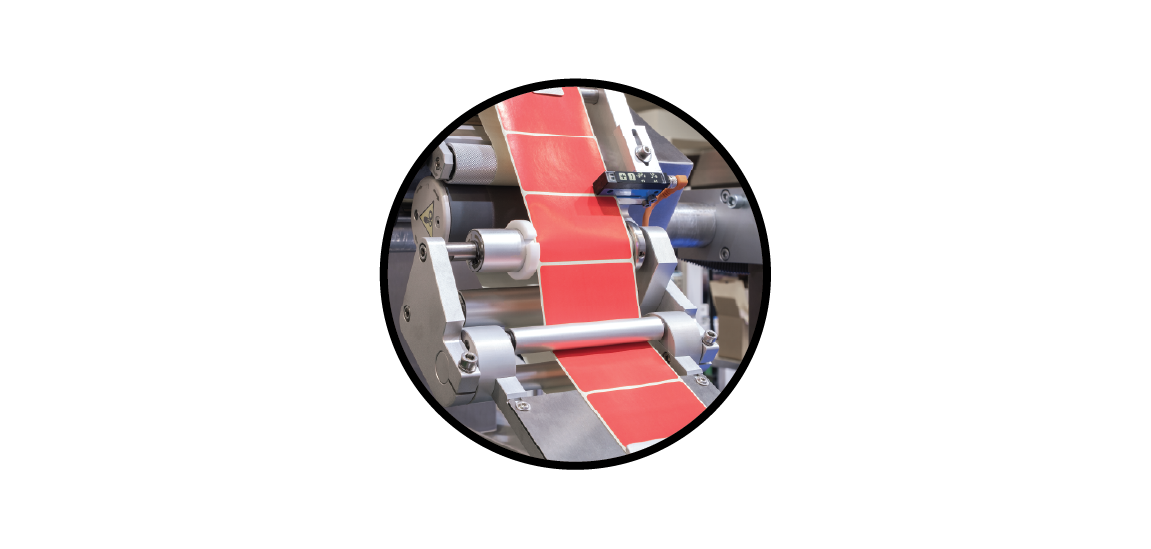

Label Printing

Our state of the art label printing facility is the final step before moving your product into production. Every detail is meticulously inspected once your labels are printed and then sent to our production facility.

Product Filling

Our 25,000 square foot production facility is fully equipped with state of the art filling equipment that can fill package sizes ranging from 1 fl oz to 1 gallon. Combined with our high speed labelers, cappers, ink jet coders and induction sealers, we turn your orders quickly so you have product when you need it most.

Pack-out & Finished Goods

At the final stage of production, we package and palletize your finished product before sending it off with one of our trusted carriers. Care is taken every step of the way to ensure that you receive the highest quality and best looking product.

Get a Quote

Send us a message and we will quickly respond to any questions you have. Want to speak to someone immediatley? Call us: 877-396-6634

LOCATION

2 Fox Industrial Dr

Madison, IL 62060

FOLLOW US